Additive Manufacturing

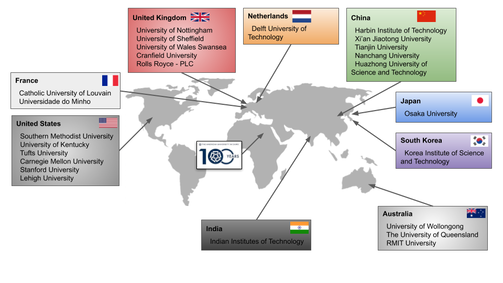

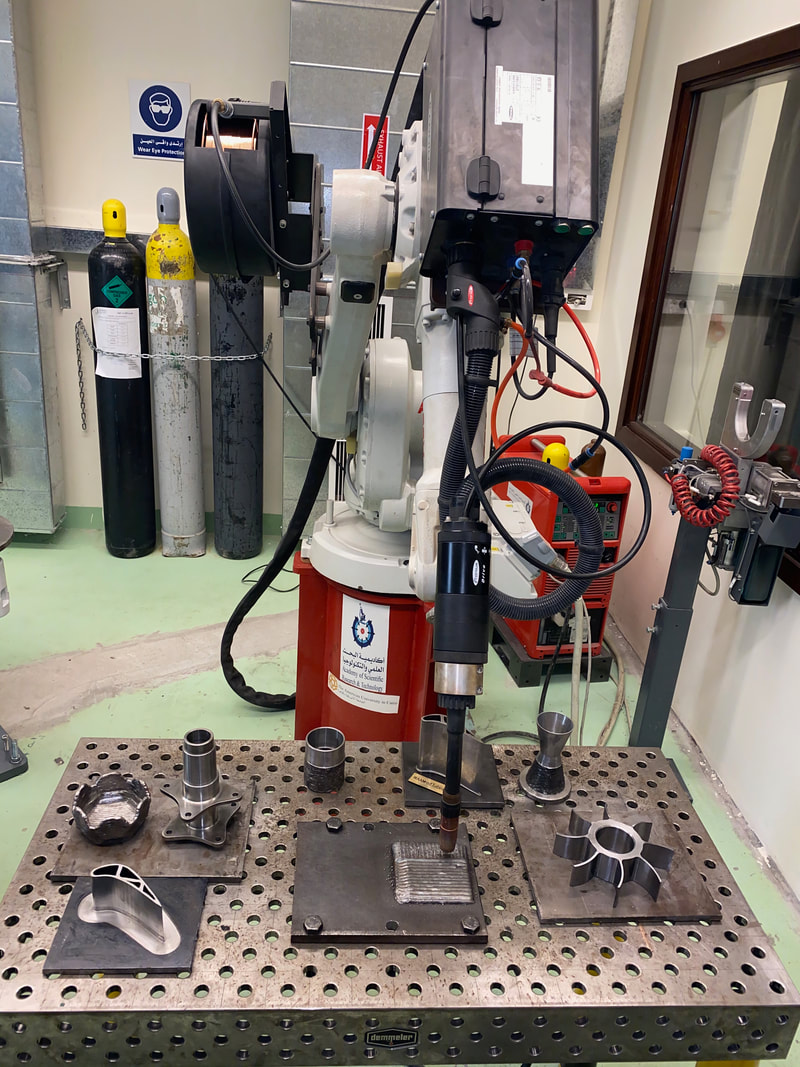

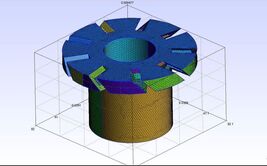

The Additive Manufacturing Centennial Lab utilizes cutting edge wire-based additive manufacturing (3D printing) technology to provide means of manufacturing and renovation of medium-to-large, metallic net-shaped parts and components. The technology provides engineering solutions with high precision, excellent mechanical properties, while being cost effective and sustainable. The exceptional efficiency and rapid productions rates of the process makes it preferable to traditional manufacturing processes. This technology is applicable in various industries, including aviation, automotive, marine, oil and gas, tools and molds, and biomedical implants. The AUC AM Centennial Lab is the first integrated metal additive manufacturing robotic system locally and regionally. AMCL plays active role in boosting the Egyptian industry through networking of key players in the field of AM locally, regionally and internationally. Accordingly, the AMCL is expected to expand and flourish based on self-funded based on a sustainability plan, which includes industrial partnerships, extramural research funds, and services to industry as well as capacity building programs. |

WAAM Technology

|

|

Wire Arc Additive manufacturing (WAAM) is a subcategory of AM manufacturing processes. Unlike powder based additive manufacturing, WAAM utilizes a GMAW (Gas Metal Arc Welding) torch attached to an industrial robotic arm. The configuration generates parts through layer by layer deposition of molten metal wire. Thereby, melting of the wire is achieved by an electric arc. WAAM has numerous advantages over other powder based AM processes. WAAM is unconstructed in terms of part volume and can produce much larger components. The process also provides much higher production rates with higher mechanical properties at lower costs. The feedstock of WAAM is more readily available, while metallic powders are more expensive, hazardous, and difficult to obtain.

|

HOW CAN WE HELP YOU

|

|